News 2025

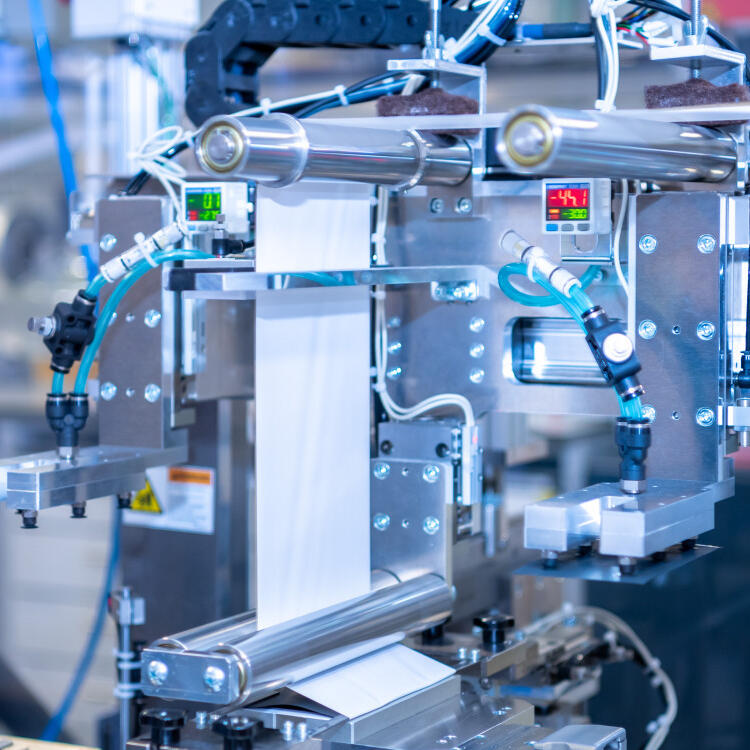

Recycling method for dry-processed cathodes developed

Lithium-ion batteries: Recycling costs vary widely

Electric vehicle batteries – Prioritize reuse before recycling

Research Assistant (E 13 TV-L)

The Institute of Business Administration at the Department of Chemistry and Pharmacy at the University of Münster, Germany, is seeking to fill the position of a Doctoral Research Associate (Wissenschaftliche*r Mitarbeiter*in, salary level E 13 TV-L, 65%) at the earliest possible date. We are offering a part-time position (65%) on a fixed-term basis for three years. Full-time employees are required to teach 4 hours per week during the semester.

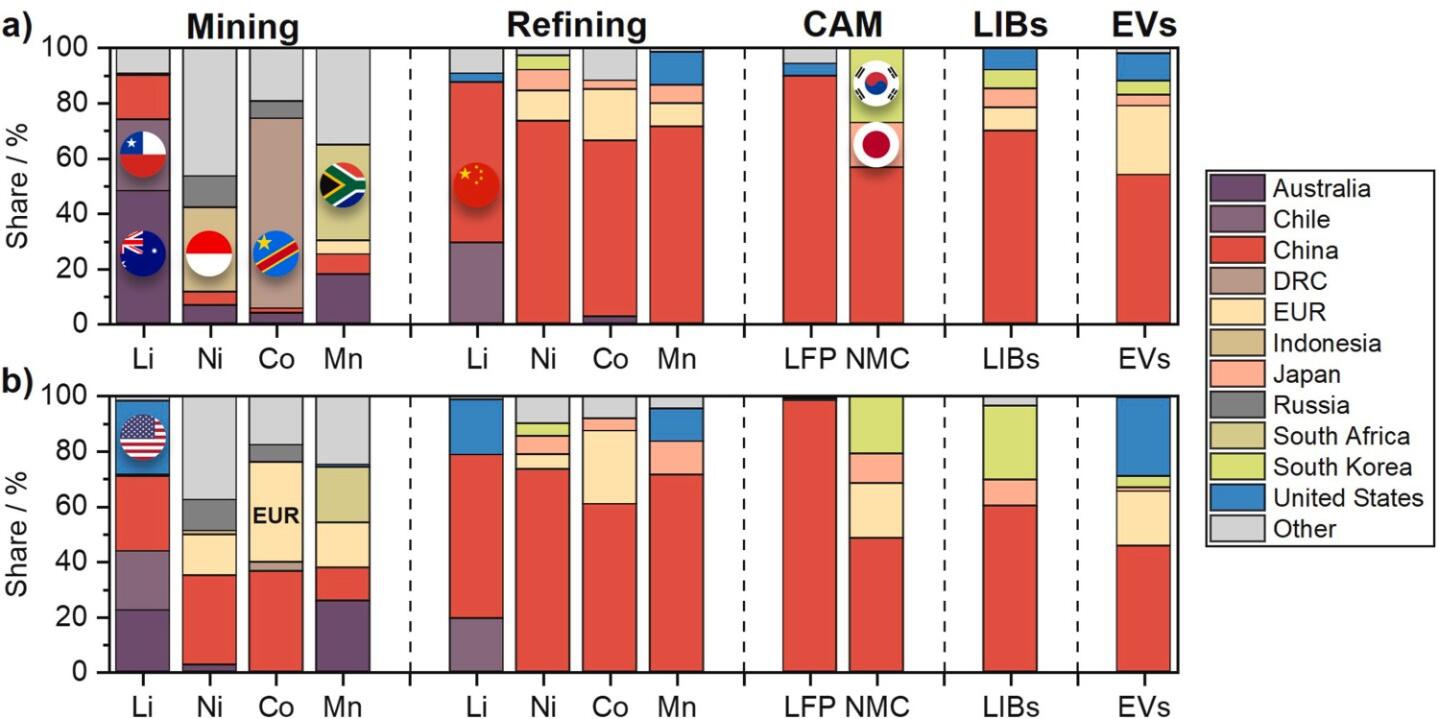

New study on the global race for future battery technologies

Research Assistant (E 13 TV-L)

The Business Chemistry Group at the University of Münster is seeking to fill a research assistant position (E 13 TV-L) with 65% of the regular weekly working hours as soon as possible. The position is initially limited to 3 years, but can be extended in the context of a doctorate. The full-time teaching commitment is 4 SWS.