Contents

- Physical Vapor Deposition (PVD)- Edwards Auto 306

- Sputtering system - Aja Orion 8 UHV

- Plasma Enhanced Chemical Vapour Deposition (PECVD) - Oxford Plasmalab 80+

- Sputtering system - von Ardenne LS 730S

- Electron Beam Physical Vapor Deposition (EB-PVD)

- Atomic Layer Deposition (ALD) - Cambridge NanoTech Savannah

- Au Sputter Coater Cressington 108auto

- Resist spin coaters - POLOS Spin 150i SPS europe

Deposition

Physical Vapor Deposition (PVD)- Edwards Auto 306

- 1 x E-beam source with a fourfold revolver crucible holder - up to four different materials via E-beam without breaking vacuum

- 2 x thermal (resistance heating) sources - allow in total combined with the E-beam co-evaporation of three materials

- Temperature controlled heated sample holder

- Film thickness meter with two individual sensors for E-beam and thermal evaporation

- Rotary sample holder for up to 10" wafers

- low temperature evaporation capability for molecular depositions

Contact: Stefan Ostendorp

Location: CeNTech II, lab 1.04

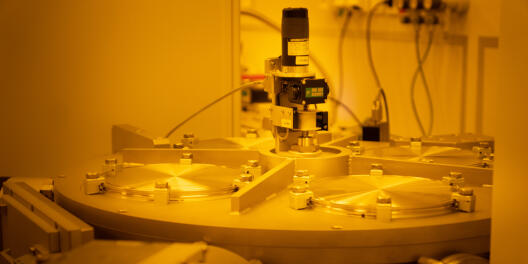

Sputtering system - Aja Orion 8 UHV

- Vaccuum Load-Lock system: main chamber under constant UHV and ten times faster sample throughput

- RF and DC sputtering

- Ar and N2 process gases

- Quartz crystal monitor for determination of deposition rate

- Substrate heating up to 1000°C

- Targets: currently in use: Nb. Available for future developments: Mo, Si, Ti, SiO2

- 4" diameter wafer substrate holder

- Uniformity +/- 2.5% (over 4" diameter wafer)

Contact: Connor Graham-Scott

Location: CeNTech I, deposition zone, 0.19

Plasma Enhanced Chemical Vapour Deposition (PECVD) - Oxford Plasmalab 80+

- Process gases: SiH4, N2, N2O, NH3, C4H8

- Deposition of SiN, SiO2, Si..

Contact: Maik Stappers

Location: SoN, plasma zone

Sputtering system - von Ardenne LS 730S

- Magnetron-Sputtersources: Aluminium (Al) and Silver (Ag), Glass (SiO2) and Indium Tin Oxide (ITO)

- DC-Generator: DFG 1500 DC (1.5 kW) for high-rate-sputtering of 50 nm to 1 µm layers

- RF-Generator: A600RF/MU (600 W) for sputtering of non-conductive materials

- Vacuum pressure: ~ 5 x 10-7 mbar

- Processing pressure: 10-3 mbar (with Argon flow)

- Sample size: < 4”-Substrates in sputter-up-mode (Sampleholder for various chip sizes)

Contact: Maik Stappers

Location: CeNTech I, deposition zone, 0.19

Electron Beam Physical Vapor Deposition (EB-PVD)

- Beamtec Electron beam evaporator EBM-6II

- Elite 4 controller with beam deflection tracking system

- 4 kW high voltage stage

- 8 x 4 cm3 Crucibles System

- Available materials: Au, Al, Cr, Cu, ITO, SiO2, Ti

Contact: Matthias Volz

Location: CeNTech I, deposition zone, 0.19

Atomic Layer Deposition (ALD) - Cambridge NanoTech Savannah

- Deposition of (mainly) metal oxides with monolayer accuracy

- Typical deposition materials:

- water (oxygen source)

- Tantalum oxide

- Zinc oxide

- Titanium oxide

- Aluminum oxide

- Tin oxide

- Tungsten oxide

- Iron oxide

- Three heated slots for metal precursors, one unheated for water as oxygen source

- No ozone source or plasma generator included

Contact: Stefan Ostendorp

Location: CeNTech I, lab 2.23

Au Sputter Coater Cressington 108auto

Manual sputter coater

- Sputter head of Low voltage planar magnatron

- Gold fitted as standard (Au/Pd or Pt optional) - 57mm Ø x 0.1mm thick

- Current control independent of vacuum - Variable 10 - 40mA

- Power - 40 VA max (excluding rotary pump)

Contact: Riya Gupta

Location: CeNTech I, deposition zone, 0.19

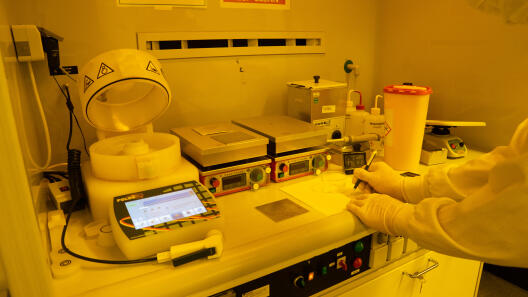

Resist spin coaters - POLOS Spin 150i SPS europe

- For E-beam resists and photoresists

- Speed: 0 -12 000 rpm

- Spin processor for cleaning, drying, coating, developing and/or etching of up to Ø 160 mm substrates

- 1 x table top, 1 x wet bench integrated

- Rotation direction (CW, CCW, puddling)

- Full-Plastic System in Natural Polypropylene (NPP)

- Easy, step- by- step recipe programming via large colour touchscreen

Contact: Maik Stappers

Location: CeNTech I, preparation zone, 0.15