Get started with our machines

The Munster Nanofabrication Facility (MNF) is equipped with a wide range of machines for deposition, etching, lithography, wet processing, thermal processing, metrology and packaging. (Click on the tab below to see a complete list of our equipment.)

To get started with our machines:

- Apply to join the MNF and complete the MNF Introduction tutorial

- Get training on your instrument(s) from one of our instrument managers

- See maps of the cleanrooms on our location page

- View operation instructions and recipes in the MNF-Wiki (registration is required for first-time users)

- Visit GitHub to see the GDSHelpers Library for E-beam and Nanoscribe users

- ...Familiarize yourself with the safety information below.

View a COMPLETE LIST of our machines __click to expand__

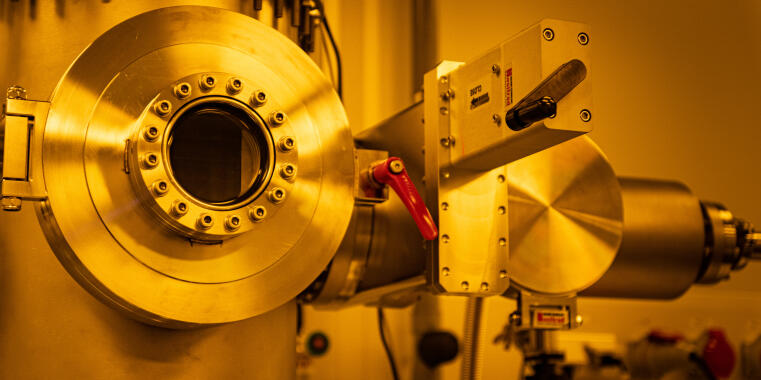

Deposition

- Physical Vapor Deposition (PVD)- Edwards Auto 306

- Sputtering system - Aja Orion 8 UHV

- Plasma Enhanced Chemical Vapour Deposition (PECVD) - Oxford Plasmalab 80+

- Sputtering system - von Ardenne LS 730S

- Electron Beam Physical Vapor Deposition (EB-PVD)

- Atomic Layer Deposition (ALD) - Cambridge NanoTech Savannah

- Au Sputter Coater Cressington 108auto

- Resist spin coaters - POLOS Spin 150i SPS europe

Plasma Etching

- Reactive Ion Etcher (RIE) - Oxford PlasmaPro 80

- Inductively Coupled Reactive Ion Etcher (ICP RIE) - Oxford PlasmaPro 100

- Plasma Asher- Diener Zepto-W6

Wet Etching:

Grinding and polishing

Lithography

- Electron beam lithography - Raith EBPG5150

- Dual beam Si/Au Focus Ion Beam (FIB)/ SEM - Raith VELION

- Beam pen lithography- TERA-print

- Polymer pen lithography- n.able Molecular Printer

- Mask aligner - Karl Suss MA56

- Nano Imprint Lithography System - EVG620 NT

- Nanoscribe Quantum-X Align

- 3D Lithography - Nanoscribe Photonic Professional GT

- Helium/Neon Focused Ion Beam (FIB) – Zeiss ORION NanoFab

Wet processing

- E-beam preparation wet bench

- Critical Point Dryer - Leica EM CPD300

- Photoresist wet bench- Arias

- Organic material wet bench- Arias

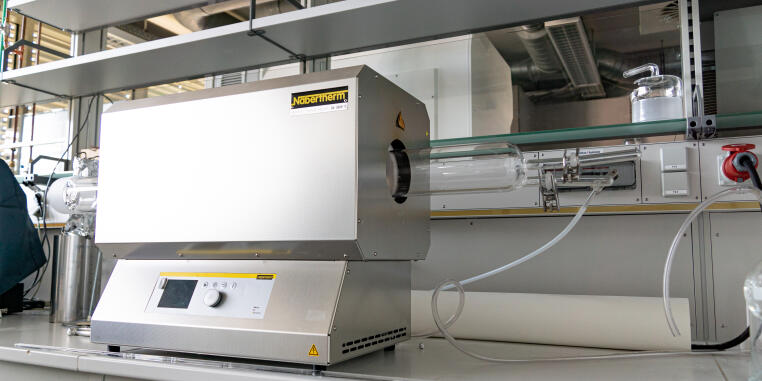

Thermal processing

Metrology

- Transmission Electron Microscope (TEM)- Thermo Fisher Scientific FEI TITAN Themis G3 60-300

- Dual Beam microscope (SEM / FIB)- Zeiss CrossBeam 340

- Scanning Microscope (LSM)- Keyence VK-X

- Scanning Electron Microscope (SEM) - JEOL JSM-IT100

- Scanning Near-Field Optical Microscopy (SNOM) - neaSNOM

- Film thickness measurement - Filmetrics F20

- Time-of-Flight- Secondary Ion Mass Spectroscopy (TOF-SIMS) - Cryo-IONTOF M6 Special Edition

- Ellipsometer - Woolam M-2000

- Film thickness measurement system- Toho Spec 3100

- Atomic Force Microscopy (AFM)- NanoScope Icon, Bruker

- Atomic Force Microscopy (AFM)- Bioscope Resolve, Bruker

- Atomic Force Microscopy (AFM)- Nanowizard 3, JPK-Bruker

- Probe Station- Cascade MPS150

- Optical microscope - Nikon Eclipse LV100ND

Packaging

Book your instrument

If you are a member of the MNF and are trained on your instrument, you may use the booking system to reserve time-slots for your instrument. For details on our booking system and how to register, visit our Learnweb portal.

Please note: Use of the MNF equipment incurs a monthly fee. For details, view the fee table.

Safety

MNF Introduction tutorial in our Learnweb portal (password “mnf123”)

Available materials and Material Safety Data Sheets (MSDS)

General operational safety instructions

Working Safely in Chemical Labs / Sicheres Arbeiten in Chemie Laboren

DGUV: "Working safely in laboratories" / "Sicheres Arbeiten in Laboratorien"

Camera surveillance

To ensure your safety, the MNF has surveillance cameras installed in the SoN and CeNTech cleanrooms. For details on your privacy and rights while under surveillance, please read the privacy statement.