Innovative Coating Technique Improves Capacity and Stability of Lithium-ion Batteries

Due to their high energy density, cathodes consisting of layered transition metal oxides, in particular nickel-manganese-cobalt-oxide cathodes (NMC), are the most common and versatile active materials for lithium-ion batteries. However, NMC is prone to various degradation effects that result in the loss of battery cell capacity. A promising approach to counteract these mechanisms and thus improve the electrochemical performance, thermal properties and surface structural stability is the surface coating of cathode materials. In a new study, a team from MEET Battery Research Center and the Institute of Materials Physics at the University of Münster applied an innovative technique for the first time that enables not only direct coating but also control of the coating thickness.

Coated NMC Cathodes Provide Advantages

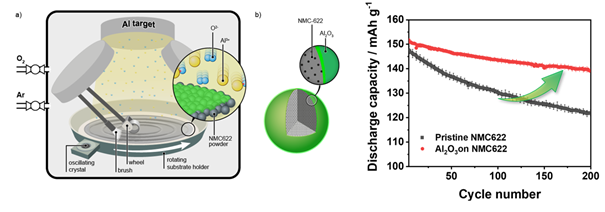

The causes for the capacity loss of NMC cathodes are wide-ranging: In addition to moisture uptake and the development of oxygen, impurities can form at the particle surface or transitions metals can dissolve. Moreover, particles can crack during charging and discharging cycles or at elevated temperatures. To prevent these effects, the scientists coated the NMC cathodes with a protective layer of aluminum oxide. For the first time, they applied a novel technique developed at MEET Battery Research Center that is based on radio-frequency magnetron sputtering. “The resulting coatings are homogeneous, have good surface coverage and their thickness can be controlled,” explains Atif Javed, PhD student at MEET Battery Research Center and the international Graduate School BACCARA (Battery Chemistry, Characterization, Analysis, Recycling and Application).

The result: Cells with coated NMC cathodes retained more capacity during charging and discharging than cells with uncoated cathodes. They also demonstrated greater thermal stability, less structural degradation and less particle cracking. “On the one hand, our study paved the way for research on the novel coating technique for other materials, depending on the requirements,” says Javed. “On the other hand, the results show that the lithium-ion battery has the potential for further improvement.”

Study Published in Batteries & Supercaps

Authors of the study are the researchers Atif Javed, Feleke Demelash, Egy Adhitama, Bastian Heidrich and Dr Markus Börner (MEET Batterry Research Center), Prof. Dr Martin Winter (MEET Battery Research Center and Helmholtz Institute Münster) as well as Ardavan Makvandi, Dr Martin Peterlechner and Prof. Dr Gerhard Wilde (Institute of Materials Physics at the University of Münster). The entire study was published as an open access article in the journal “Batteries & Supercaps”.