Electrochemical Energy Storage Technologies

The Business Chemistry team complements Münster's strength as a leading international location for battery research. Our interdisciplinary team develops new methods for modelling battery costs, scaling battery production and systematically analysing trends in basic research and industrial development of new battery technologies.

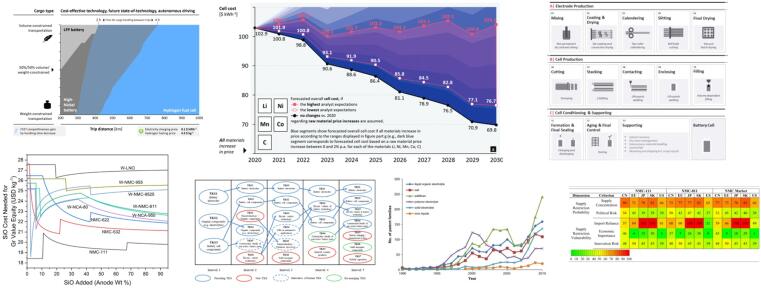

One focus of our work is on the development of models for the economic evaluation of batteries and individual components.[1,2] Results of our research have, for example, provided new insights into the future development of battery costs [3] and costs in large-scale battery production [4].

In addition, our team has developed skills in the analysis of future battery technologies.[5,6] For example, our studies have provided new insights into the application of machine learning to analyze development trends [7] and the effective technology choice for long-haul battery-powered vehicles [8].

Another focus of our research is the investigation of production infrastructure and location decisions for new battery factories, as well as the analysis of battery supply chains.[9, 10, 11]

[1] Mauler, L., Lou, X., Duffner, F., & Leker, J. (2022). Technological innovation vs. tightening raw material markets: falling battery costs put at risk. Energy Advances, 1(3), 136-145.

[2] Greenwood, M., Wentker, M., & Leker, J. (2021). A bottom-up performance and cost assessment of lithium-ion battery pouch cells utilizing nickel-rich cathode active materials and silicon-graphite composite anodes. Journal of Power Sources Advances, 9, 100055.

[3] Mauler, L., Duffner, F., Zeier, W. G., & Leker, J. (2021). Battery cost forecasting: a review of methods and results with an outlook to 2050. Energy & Environmental Science, 14(9), 4712-4739.

[4] Duffner, F., Mauler, L., Wentker, M., Leker, J., & Winter, M. (2021). Large-scale automotive battery cell manufacturing: Analyzing strategic and operational effects on manufacturing costs. International Journal of Production Economics, 232, 107982.

[5] Wagner, R., Preschitschek, N., Passerini, S., Leker, J., & Winter, M. (2013). Current research trends and prospects among the various materials and designs used in lithium-based batteries. Journal of Applied Electrochemistry, 43, 481-496.

[6] Greenwood, M., Wrogemann, J. M., Schmuch, R., Jang, H., Winter, M., & Leker, J. (2022). The Battery Component Readiness Level (BC-RL) framework: A technology-specific development framework. Journal of Power Sources Advances, 14, 100089.

[7] Aaldering, L. J., Leker, J., & Song, C. H. (2019). Analysis of technological knowledge stock and prediction of its future development potential: The case of lithium-ion batteries. Journal of Cleaner Production, 223, 301-311.

[8] Mauler, L., Dahrendorf, L., Duffner, F., Winter, M., & Leker, J. (2022). Cost-effective technology choice in a decarbonized and diversified long-haul truck transportation sector: A US case study. Journal of Energy Storage, 46, 103891.

[9] Duffner, F., Kronemeyer, N., Tübke, J., Leker, J., Winter, M., & Schmuch, R. (2021). Post-lithium-ion battery cell production and its compatibility with lithium-ion cell production infrastructure. Nature Energy, 6(2), 123-134.

[10] Duffner, F., Kraetzig, O., & Leker, J. (2020). Battery plant location considering the balance between knowledge and cost: A comparative study of the EU-28 countries. Journal of Cleaner Production, 264, 121428.

[11] Greenwood, M., Wentker, M., & Leker, J. (2021). A region-specific raw material and lithium-ion battery criticality methodology with an assessment of NMC cathode technology. Applied Energy, 302, 117512.