Battery Safety

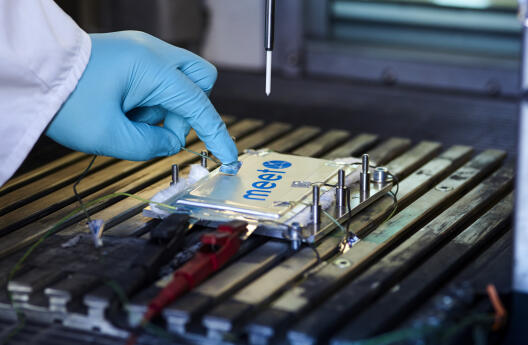

MEET researchers produce particularly pioneering work regarding battery safety. For this purpose, our research institute runs a battery safety lab, in which battery cells and small modules with a capacity of up to 100 ampere hours are given a thorough examination. Four test chambers are available for mechanical, electrical and thermal safety examinations. The so-called abuse tests push the battery cell to its limits – for example, through overloading, mechanical damage, or thermal stress with temperatures which are too high or too low. Our researchers’ aim is to develop battery materials and designs which increase the intrinsic safety of batteries.

Safety over the Entire Battery Lifecycle

As our researchers carry out their examinations with cells produced specifically for this purpose, they have precise knowledge of the materials used and can therefore draw exact conclusions about where and why reactions occur which constitute a safety hazard. A special feature at MEET is that the team examines battery safety not only at the beginning, but over the entire battery lifecycle. Synergy effects arise in the process through intense collaboration with the team from the Battery Aging competence area.

Classic safety tests such as the nail penetration are also carried out by the MEET team in the battery safety lab, named BaSiL. In addition, battery safety is always examined at various levels of the cell, so that decisive materials, components and cell states can be identified. These, in turn, can be evaluated over a wide scaling range – from coin cells up to large-format cells. All these examinations are indispensable to ensuring a battery cell’s safe operation over its entire lifecycle and under a very wide range of conditions. In addition, the findings made and test methods used in the field of lithium-ion technology are transferred to future systems with lithium-metal or solid-state batteries and adapted correspondingly in order to validate their safety properties too.