Cell and Cell Design

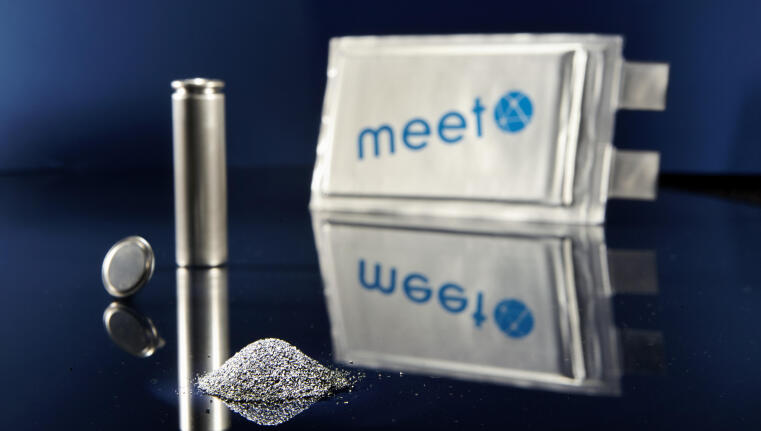

MEET develops new materials and processes and aims to understand the way they function. It is essential to ensure that the active materials and components exhibit the best possible physico- and electrochemical properties. Also, they need to be superior to the State-of-the-Art considering the interaction with other materials and components in the overall cell system. Goals are enhanced safety properties, longevity, high energy density and cost effectiveness.

Thus, this research focuses on the following fields:

- Process development from material to cell, in cooperation with technical universities, industry partners and small- and medium-sized enterprises

- Improving battery materials on lab-scale and examining the interaction of components in the composite electrode

- Upscaling from lab- to pilot-plant-scale and investigation of process parameter-property relationship within the system

- Optimization of battery cell manufacturing in the pilot plant production facilities: Among other steps this includes mixing, coating, slitting and assembly

The upscaling of small laboratory cells to larger cells with several ampere-hours that are suitable for application in motor vehicles is another focus of the competence field. Therein, the objective is to examine the transferability of the results from laboratory experiments to pilot-plant-scale and optimize accordingly the design of electrodes and cells and their processing. Thus, the competence field closes the gap between laboratory and practical application on a pilot-plant-scale. New active materials, which are only available in limited quantities, are characterized by using an application-oriented prototype.

In addition, the "Cell & Cell Design" team develops standard recipes and components with extremely high reproducibility for various applications to support projects in other MEET divisions.