High-performance Cathodes with High Mass Loading Developed by Combining Two Conductive Additives

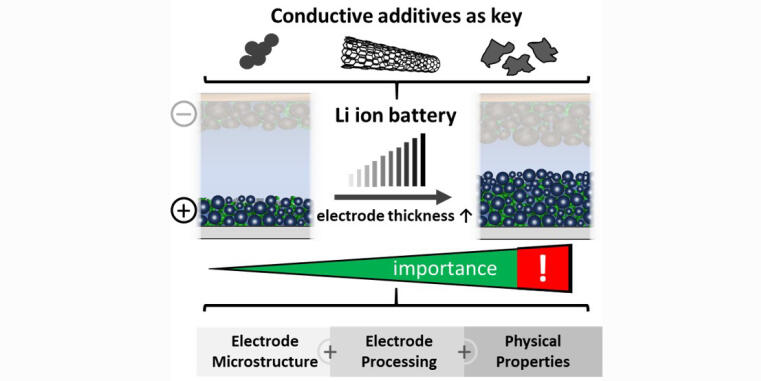

To further increase the energy density of batteries and simultaneously reduce production costs, even thicker electrodes with a high mass loading are required. While new material concepts such as silicon oxide or lithium metal with high specific capacities are being developed for the anode, the cathode remains a limiting factor. A team from MEET Battery Research Center at the University of Münster and the Technical University Braunschweig has now investigated how the cathode – initially for lithium ion batteries – can be formulated in such a way that it can be processed efficiently and at the same time provide a high, stable electrochemical performance. The scientists paid particular attention to the influence of various conductive additives.

Combination of Conductive Graphite and Carbon Nanotubes Provides Promising Results

Previous research has focused either on improving the electrode formulation or its processing. “In our approach, we combine both and investigate the material selection as well as the process optimization,” explains MEET researcher Candeniz Gercek. To this end, the scientific team analyzed the influence of four different conductive additives on the processing, microstructure and performance of highly mass loaded electrodes: carbon nanotubes (CNTs), conductive graphite (CG), carbon black (CB) and carbon microfibers (CMF). “Our research has shown that the combination of conductive graphite and carbon nanotubes is particularly effective,” says Gercek. It improves both the processing – for example through better viscosity and a higher solid content – as well as the electrical conductivity, rate capability and long-term stability of the electrode.

The study also proves that the combined use of the two conductive additives enables electrodes with a high mass loading and a surface capacity of eight milliampere-hours per square centimeter (mAh/cm2) without a loss of performance. “Microstructure and electrochemical performance correlate with each other. By using both CG and CNTs, we can increase the fast-charging capacity and lifetime of the battery cells in the long term and at the same time produce more sustainably by reducing solvent consumption,” Gercek provides an outlook.

Entire Study Available

The detailed results have been published by the authors Candeniz Gercek, Johanna Kauling, Chirag Vankani and Dr Markus Börner, MEET Battery Research Center, Julian K. Burmeister and Prof. Dr Arno Kwade, Institute for Particle Technology at Technical University Braunschweig, as well as Prof. Dr Martin Winter, MEET Battery Research Center and Helmholtz Institute Münster, in the journal “Advanced Energy and Sustainability Research”.