MEET Team Optimizes Carbon Black Distribution in LFP-Based Electrodes

Conductive electrode additives such as graphite or carbon black are indispensable inactive components of lithium ion battery electrodes. These contain active materials with limited electronic conductivity, such as lithium iron phosphate (LFP). A study by MEET Battery Research Center at the University of Münster as part of the completed ProLiT project (process and material development of lithium ion battery cathodes for large-scale dry coating) focused on the distribution of these additives and their effects on the conductive carbon binder domain (CBD) of a cell. The study focused on the question of how a pre dry mixture of LFP and conductive carbon black, as already used in nickel-manganese-cobalt cells, affects the conductivity and performance of the electrodes.

Cells Exhibit Higher Rate Capability and Long-term Stability

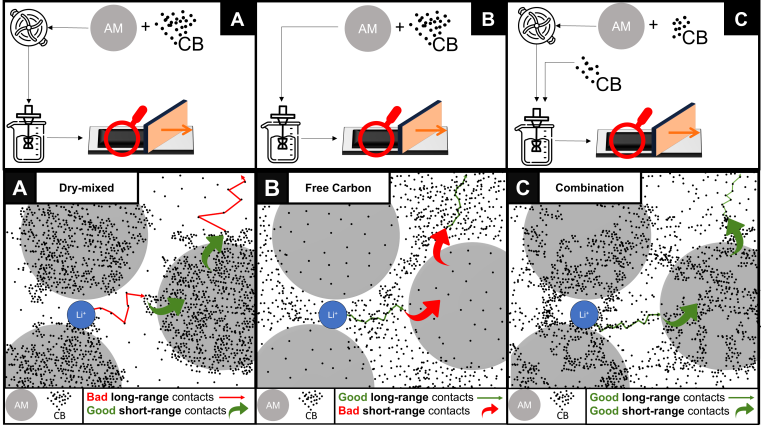

“The approach of dry mixing LFP and conductive carbon black in advance is considered a simpler and more cost-effective alternative that can be integrated into existing mixing processes during electrode production,” says scientist Simon Raffenberg, explaining the meaning of the study. However, the MEET research team found that the conductivity and performance of electrodes in which the entire carbon black content was dry-premixed with LFP deteriorated at high discharge rates. The researchers attribute this to changes in the electronic contacts in the near and far field within the CBD of the electrode.

To counteract these changes, the scientists' next step was to dry-mix only part of the conductive carbon black with the LFP and add the remaining part as “free carbon” only during the production of the electrode paste. "This procedure enabled us to improve the performance of the cells again. In addition, the electrodes produced in this way even exhibit higher rate capability and long-term stability than the conventionally produced reference cells," summarizes Raffenberg. The investigations have demonstrated a scalable process step for optimizing the carbon binder area in electrodes, which can be transferred to other battery materials with inherently low conductivity.

Entire Study Available

The detailed results have been published by the authors Simon Raffenberg, Dr Markus Börner and Dr Katrin Junghans, MEET Battery Research Center, as well as Prof. Dr Martin Winter, MEET Battery Research Center and Helmholtz Institute Münster of Forschungszentrum Jülich, in the journal “Journal of The Electrochemical Society”.