Innovative Pre-Lithiation Process for Silicon Anodes Developed

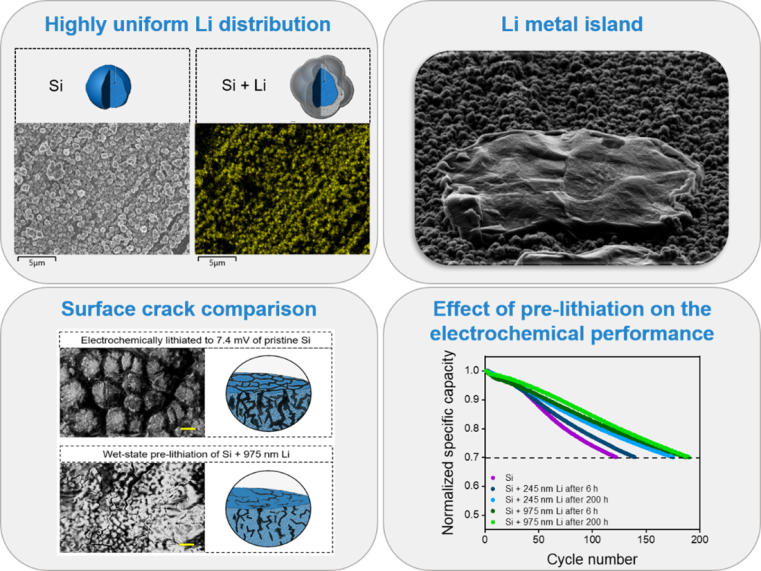

Silicon (Si) is one of the most promising anode materials to replace state-of-the-art graphite anodes and further push the energy density of lithium-ion batteries (LIB). However, Si anodes suffer from large volume expansions during battery operation leading to mechanical degradation, which induces a loss of active material and thus continuously exposes the highly reactive surface to the electrolyte. The resulting loss of active lithium can lead to rapid battery cell failure. To overcome this, scientists of MEET Battery Research Center at the University of Münster have developed a new pre-lithiation technique based on the thermal evaporation of lithium metal in pure Si anodes. Rather than dealing with inevitable volume expansion, pre-lithiation is aimed at compensating for active lithium losses.

Precise Control of the Degree of Pre-Lithiation and Lithium Metal Deposition

Researchers have already developed various strategies towards a practical implementation of Si anodes, for example by an advanced design of Si particles or by using novel binder systems. However, the exacerbation of huge volume expansion is still inevitable. “Pre-lithiation of the Si-based anode is considered as a highly appealing approach where we focus on compensating for lithium losses. Using this technique, a certain amount of excess active lithium is stored in the electrode prior to battery cell operation,” explains Egy Adhitama, doctoral student at the International Graduate School for Battery Chemistry, Characterization, Analysis, Recycling and Application (BACCARA) and MEET Battery Research Center. The thermal evaporation of Li metal for pure Si anodes allows both, precise control of the degree of pre-lithiation and a homogeneous Li metal deposition at the surface of the electrode. By varying the degree of pre-lithiation, the scientists were able to precisely determine the influence of the vapor-deposited lithium on prolonging cycle life.

In addition, the research team explored the impact of the typical liquid carbonate-based electrolyte on the reaction mechanism of the pre-lithiation. Based on these results, the process in the dry- (without electrolyte) and wet-state (with electrolyte) was revisited. An electrochemical characterization was used to validate the active lithium losses. MEET scientist Dr Aurora Gomez-Martin says: “Our approach overcomes the limitations of previous techniques and thus represents an important step towards Si-based LIB cells with high energy density and longer cycle life.”

Complete Study Open Access

The detailed results of their study have been published by Egy Adhitama and Atif Javed, MEET Battery Research Center and International Graduate School BACCARA, Dr Frederico Brandao, Iris Dienwiebel, Marlena Bela, Lukas Haneke, Dr Marian Stan, Dr Aurora Gomez-Martin and Dr Tobias Placke, MEET Battery Research Center, and Prof Dr Martin Winter, MEET Battery Research Center and Helmholtz Institute Münster, in the scientific journal “Advanced Functional Materials”.