Combined Mitigation Strategies in Ni-rich NCM Cathode Materials Improves Battery Cell Performance

For high-energy lithium ion batteries, nickel-rich layered oxides such as lithium nickel cobalt manganese oxide (NCM) are considered a promising cathode material. Thermal and cycling stability issues originating from increasing Ni contents are often addressed by mitigation strategies such as elemental bulk substitution and surface coating. Although both approaches separately improve battery cell cycling stability, there is limited work investigating the combination of these strategies. In a joint research project of University of Münster, Forschungszentrum Jülich and Johannes Gutenberg-Universität Mainz, the influences between both approaches were analysed and positive effects on cycle life by the combination of strategies were investigated.

Instability Issues Hinder Practical Application

Ni-rich layered oxide cathodes with nickel contents above 80 per cent provide an increased energy density on the material level compared to state-of-the-art materials and require less cobalt as a critical raw material. However, their practical use in lithium ion batteries for automotive applications, for example, is hindered by severe instability challenges and degradation mechanisms. These challenges are often addressed in academia and industry by mitigation strategies such as elemental bulk substitution – so called “doping” – and surface coating to minimize parasitic side reactions with the electrolyte. However, for complete stabilization of very Ni-rich layered oxide cathodes, these approaches are not sufficient on their own, despite their positive effects. A combination of different modification strategies might be needed for the successful integration in practical cells.

Decisive Influences and Interactions of Dopants

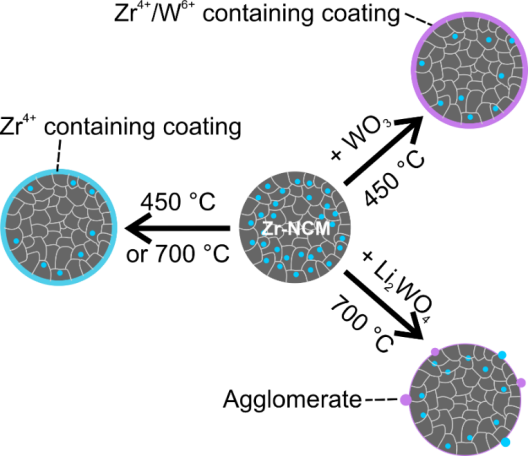

A team of scientists led by battery researcher Friederike Reissig from Helmholtz Institute Münster (HI MS) at Forschungszentrum Jülich demonstrated that the combination of zirconium (Zr) as a frequently used dopant in commercial Ni-rich layered oxide cathode materials with tungsten (W)-containing coatings improves the cycling stability. Only the heat-treated-only reference samples without coating show an even more significant improvement.

The improved cycling stability originates from the Zr4+ dopant diffusing to the surface at temperatures below the synthesis temperature due to its low solubility. Friederike Reissig explains: “With an additional W-containing surface coating, this is disrupted, and various other compounds form on the surface in the form of a homogeneous layer or agglomerates, depending on the temperature and solvent used.” MEET scientist Dr Aurora Gomez-Martin emphasizes: “This work highlights the importance of researching not only the effect of individual dopants or coatings on layered oxides, but also the influences between the two.”

Open Access Publication in ChemSusChem

The detailed results of the study have been published as an open access article in the journal "ChemSusChem". Authors are Friederike Reissig, Helmholtz Institute Münster of Forschungszentrum Jülich, Prof. Dr Wolfgang Zeier, Helmholtz Institute Münster and Department of Inorganic and Analytical Chemistry at the University of Münster, Prof. Dr Martin Winter, Helmholtz Institute Münster and MEET Battery Research Center at the University of Münster, Dr Martin Alexander Lange, Department of Chemistry of the Johannes Gutenberg University Mainz (now: Department of Inorganic and Analytical Chemistry at the University of Münster), as well as Lukas Haneke, Dr Tobias Placke, Dr Richard Schmuch and Dr Aurora Gomez-Martin, MEET Battery Research Center at the University of Münster. The work includes results from the "SeNSE" research project funded by the European Union's Horizon 2020 research and innovation program.