Prelithiation Enables Practical Implementation of Conversion-type Negative Electrodes in Lithium-Ion Cells

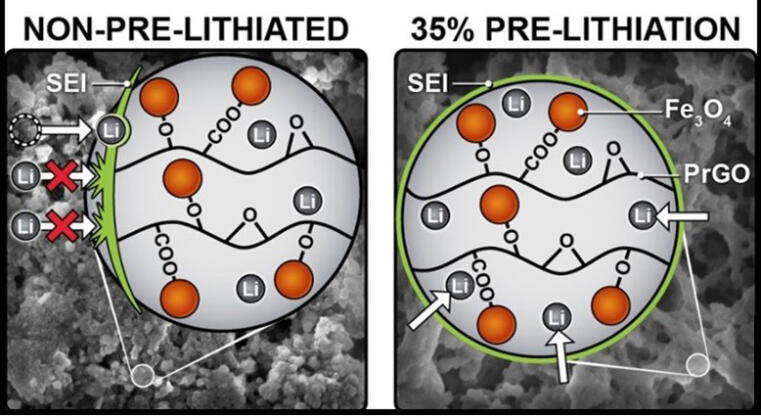

Transition metal oxides such as magnetite (Fe3O4) are alternative negative electrode materials for lithium-ion batteries owing to their high initial achievable capacities compared to state-of-the-art graphite. The involvement of a graphene-oxide network improves the conductivity and prevents the transition metal dissolution as well as Fe3O4 pulverization from the electrode. Yet it remains insufficient to enable implementation of the electrodes in practical applications, where the lithium content is initially limited. In a joint research project, scientists from MEET Battery Research Center of the University of Münster, Helmholtz Institute Münster of Forschungszentrum Jülich and Sabanci University Nanotechnology Application Center (SUNUM) investigated the benefits of the electrochemical pre-lithiation in terms of formation of a stable solid electrolyte interphase (SEI) on the material´s surface. This successfully prevents active lithium losses, even when coupled with the high energy density lithium nickel cobalt aluminium oxides (NCA) positive electrode.

Boosting of Cycle Life by Passivation of the Electrodes

The negative electrode material consists of ultrafine Fe3O4 nanoparticles attached through a three-dimensional graphene oxide-based network. Electrochemical pre-lithiation enables the uniform lithiation of the complex electrode material. MEET scientist Dr Aurora Gomez-Martin explains: “The technique also allows a controllable prelithiation degree of the negative electrode resulting in the preformation of a more homogeneous SEI prior to cycling. This restrains the formation of cracks as well as aids in the passivation of the NCA electrodes, leading to a longer cycle life.” Dr Buse Bulut Köpüklü from SUNUM in Istanbul, who completed an eight-month internship at MEET Battery Research Center and is currently working in E-Lyte Innovations, adds: “The internal resistance development of the prelithiated cells becomes less pronounced due to the reduced decomposition of the electrolyte on the electrodes surfaces.” Parasitic reactions resulting in active lithium loss are thus significantly reduced, which was a major issue associated with the practical implementation of conversion negative electrodes in full cells.

Ekin Esen, Research Associate at Helmholtz Institute Münster, concludes: “The study indicates for the first time the applicability of electrochemical prelithiation as a simple and effective method for the use of the investigated conversion-type negative electrode materials in lithium-ion batteries.”

Complete Study Published in “ACS Applied Materials and Interfaces”

The detailed results of their study have been published by Dr Aurora Gomez-Martin, Dr Tobias Placke, Dr Richard Schmuch, MEET Battery Research Center, Ekin Esen, Helmholtz Institute Münster, Prof. Dr Martin Winter, MEET Battery Research Center and Helmholtz Institute Münster, Dr Buse Bulut Köpüklü, Prof. Dr Selmiye Alkan Gürsel and Assoc. Prof. Dr Alp Yürüm, Sabanci University Nanotechnology Application Center, Istanbul, in the scientific journal “ACS Applied Materials and Interfaces”.