Pre-Lithiation Additive for the Cathode Prolongs Battery Life Cycle

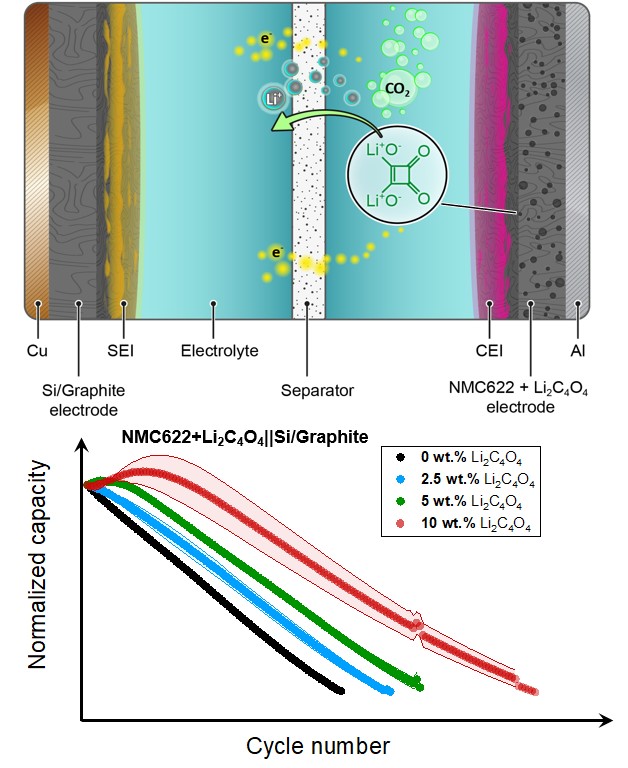

For future high energy-density lithium-ion batteries (LIB), silicon (Si) is considered the most promising high-capacity active material for the negative electrode. However, massive volume changes occur within the cell during battery operation, leading to active lithium losses, capacity fading and cell failure. In a recent study, a team of scientists from MEET Battery Research Center at the University of Münster, the International Graduate School BACCARA and Helmholtz Institute Münster of Forschungszentrum Jülich were able to prove that lithium squarate (Li2C4O4) as a pre-lithiation cathode additive can prolong battery life cycle when using Si-based anode materials. At the same time, the researchers identified challenges of the additive that need to be solved by further research. The comprehensive investigation provides important foundations on the way to the possible commercialisation of the promising Si-based LIBs.

Use of Pre-Lithiation Additives Possible Without Additional Production Step

Pre-lithiation with the help of positive electrode additives has emerged as one of the most suitable scaling-up strategies to compensate for active lithium losses in lithium-ion battery cells containing Si-based anodes. Unlike many other pre-lithiation approaches that struggle with high reactivity and poor homogeneity, pre-lithiation additives can be added to the cathode paste during processing. Therefore, an additional production step is not necessary. Maike Gnutzmann, PhD student at the International Graduate School for Battery Chemistry, Characterisation, Analysis, Recycling and Application (BACCARA) and MEET Battery Research Center, explains: "Cathode additives release an excess of lithium from the positive electrode in the first cycle, which can compensate for active lithium losses. However, despite several lithium compounds have been investigated as cathode additives so far, most of them are unstable in ambient atmosphere or incompatible with standard cathode processing protocols."

Li2C4O4 is considered a promising additive for pre-lithiation due to its air stability and compatibility with standard industrial processing. The researchers were able to show that the cycle life of Si-based LIB cells is linearly prolonged with the additive content within the cathode. MEET scientist Dr Aurora Gomez-Martin says: "This is due to the excess of active lithium provided by the additive in the first charge that can compensate for solid electrolyte interphase (SEI) formation at the anode surface. Moreover, the CO2 released, as side product after additive decomposition, can serve as electrolyte additive for the anode SEI during both, the formation cycles as well as during subsequent cycling."

At the same time, the team of scientists identified challenges for the practical application of Li2C4O4 as a cathode additive: The resulting porosity and gas development during the decomposition of the pre-lithiation additive currently still prevent its use in practical cells, so further research is needed.

Complete Study Published in "Advanced Science"

The detailed results of their study have been published by Maike Michelle Gnutzmann and Egy Adhitama, MEET Battery Research Center and International Graduate School BACCARA, Dr Aurora Gomez-Martin, Lars Frankenstein, Bastian Heidrich and Dr Tobias Placke, MEET Battery Research Center, and Prof Martin Winter, MEET Battery Research Center and Helmholtz Institute Münster, in the scientific journal "Advanced Science". The work includes results from the "SeNSE" research project funded by the European Union's Horizon 2020 research and innovation program.