Magnesium Substitution in NMC Layered Cathodes Improves Lifetime of High-Energy Batteries

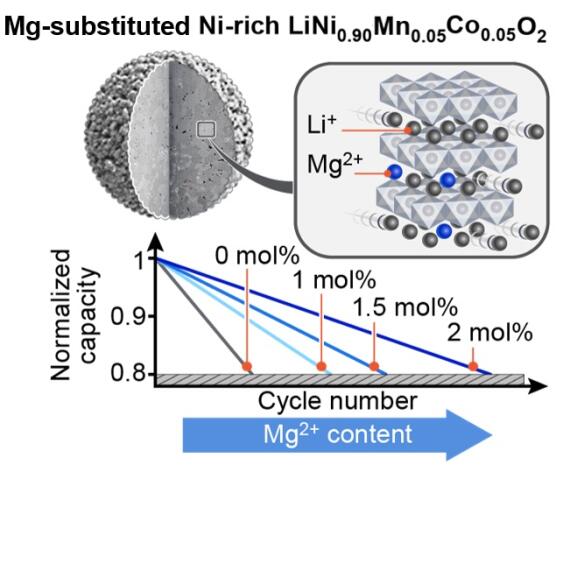

Layered transition metal oxide cathodes and in particular Ni-rich manganese cobalt (NMC-type) oxide cathodes represent the technologically most mature class of active materials for lithium ion batteries. They offer high energy density, but suffer from severe capacity degradation with repeated use. One approach to overcome these instability problems is to substitute transition metals with magnesium (Mg). Researchers from MEET Battery Research Center at the University of Münster and Helmholtz Institute Münster of Forschungszentrum Jülich have investigated the effects of magnesium substitution on the structural and electrochemical properties of Ni-rich NMC layered oxides. The team was able to demonstrate a linear correlation between cycle life and attainable gravimetric capacities, which are directly influenced by the degree of Mg substitution and the amount of Li-Ions cycled upon (de-)lithiation processes.

Element Substitution as One Possible Solution for Longer-Life Cells

In recent years, the growing demand for lithium-ion batteries with higher energy contents has triggered the development of NMC-type cathodes with steadily increasing Ni contents. This approach increases the energy density at the material level and, in most cases, also reduces the need for cobalt as a critical raw material. However, increasing the Ni content in NMC-type cathode materials inevitably results in a more complex synthesis and several structural instability issues limiting cell cycle life and safety. To further investigate elemental substitution with magnesium as a solution route, the scientific team from MEET Battery Research Center and Helmholtz Institute Münster synthesised various Mg-substituted NMC-materials with a Ni content of 90 mol% and explored them in terms of key performance metrics.

Overall, increasing the Mg content from 1 to 2 mol% linearly reduced the initial capacities and specific energies, while cycle life and thermal stability were significantly improved – due to Mg being electrochemically inactive and occupying Li sites in the layered crystal structure. MEET scientist Dr Aurora Gomez Martin explains: "The present study highlights the importance of evaluating the implications of elemental substitution on cell performance and is expected to be an insightful guideline for the future development of NMC-type cathode materials in particular with high Ni and low Co content." The researchers recommend considering a Mg content <2 mol% to achieve a higher energy density on material level and outperform state-of-the-art NMC811 cathode materials.

Full Publication in Journal "Advanced Energy Materials"

The detailed results have been published by Dr Aurora Gomez Martin, Lars Frankenstein, Marcel Heidbüchel, Dr Tobias Placke and Dr Richard Schmuch, MEET Battery Research Center, Friederike Reissig, Helmholtz Institute Münster, and Prof. Martin Winter, MEET Battery Research Center and Helmholtz Institute Münster, in the journal "Advanced Energy Materials". The paper includes results from the research project "SeNSE", funded by the European Union's Horizon 2020 research and innovation program.