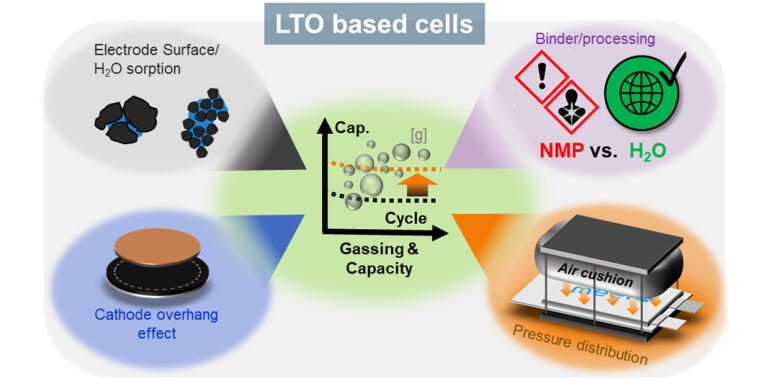

Lithium Titanate as Anode Material for Lithium Ion Batteries Investigated

Lithium titanate (LTO) is considered a promising anode material for lithium ion batteries due to its cycle life, safety properties, and rate capability. LTO has advantages over the currently used graphite anode, especially when high performance under extreme temperature conditions is required. However, the material suffers from significant gas evolution in the battery. A team from MEET Battery Research Center at the University of Münster has now investigated the influencing factors on this reaction in detail. Based on the results, the scientists analyzed previously unclarified aging mechanisms within the cells.

Focus on Electrode Surface as well as Binders and Processing Solvents

In a previous study, the researchers had already identified an approach to sustainably suppress gas evolution. High temperatures during the formation process ensured that a stable and protective decomposition layer formed on the surface of the LTO composite electrode. It successfully prevented gas evolution during cyclic aging, the continuous charging and discharging of the battery, without compromising the performance.

“Based on these results, we have now closely examined how the electrode surface, the binder, and the respective processing solvent, among other factors, affect gas evolution. A precise and comprehensive understanding of the underlying aging effects enables us to prevent gas evolution even more effectively,” explains MEET scientist Dr Lennart Alsheimer. An increased electrode surface area of the LTO-based anodes led to greater gas evolution during subsequent cyclic aging. In addition, the researchers demonstrated that aqueously processed anodes produced more gas than those that were non-aqueously processed. They also identified the pressure distribution on the electrode stack as an important factor influencing cell capacity during cyclic aging. “It is therefore an important indicator that must be considered when selecting the appropriate cell design,” says Alsheimer.

Entire Study Available

The detailed results have been published by the authors Dr Lennart Alsheimer, Dennis Kessen, Felix Dahlhaus, Dr Sascha Nowak and Dr Markus Börner, MEET Battery Research Center, as well as Prof. Dr Martin Winter, MEET Battery Research Center and Helmholtz Institute Münster of Forschungszentrum Jülich, in the journal “Batteries & Supercaps”.