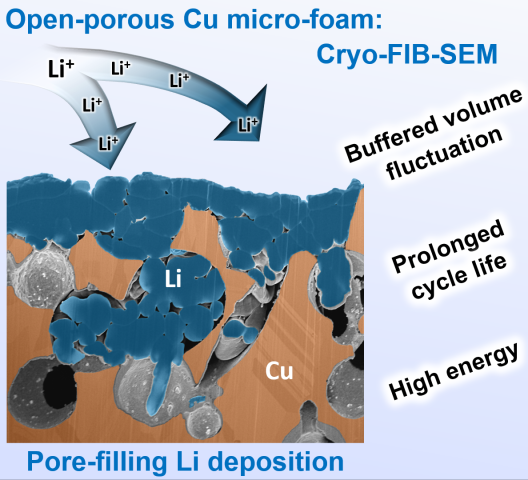

First Ion-beam Scanning Electron Microscopy Investigation of Lithium Deposition in Zero-excess Lithium Metal Batteries

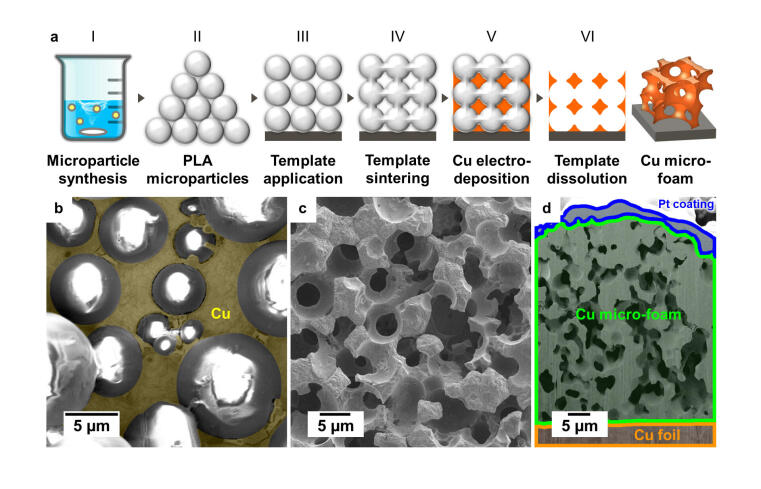

Due to their design, zero-excess lithium metal batteries (ZELMB) are thinner and lighter than standard lithium metal batteries, which means that depending on how they are constructed, they can have a higher energy density. Therefore, they have the potential to become a high-performance battery of the future. However, there is still considerable research required before they reach market readiness, particularly in the field of lithium deposition in the cell. In a joint study, scientist from MEET Battery Research Center at the University of Münster and from Helmholtz Institute Münster of Forschungszentrum Jülich have now investigated the deposition behavior of lithium in a custom-made porous copper micro-foam electrode.

Deposition Observed in More Compact, Higher Density Structures

“Previous research has shown that the use of porous deposition substrates in ZELMBs can improve their performance. However, little investigation has been done about how exactly this happens,” MEET scientist Tjark Ingber explains the research approach.

In their work, the scientists were now able to demonstrate that lithium is deposited on the copper micro-foam in more compact structures with a higher density, covering significantly less of the surface than a comparable deposition on copper foil.

Unique Images with Ion-beam Scanning Electron Microscopy

The investigation focused in particular on the initial lithium deposition in the pores below the surface that are not visible from the outside. The structures were exposed by cryogenic focused ion beam milling (cryo-FIB) and imaged in high resolution using scanning electron microscopy (SEM). Up to now, these images are unique in research on zero-excess lithium metal batteries.

Detailed 3D current density simulations highlighted how the current applied for lithium deposition is distributed in a porous substrate. Thanks to these findings, the scientists were able to formulate a mechanism for the deposition. “With these results, we pave the way to develop novel porous substrates that can further improve the performance and cycle life of zero-excess lithium metal cells,” Ingber said.

Entire Study Available Online

The detailed results of their study have been published by the scientists Tjark T. K. Ingber, Marlena M. Bela, Frederik Püttmann, Jan F. Dohmann and Dr Markus Börner, MEET Battery Research Center, as well as Dr Marian C. Stan and Dr Peter Bieker, Helmholtz Institute Münster, and Prof. Dr Martin Winter, MEET Battery Research Center and Helmholtz Institute Münster, in the Journal of Materials Chemistry A of the Royal Society of Chemistry