Innovative Approaches for Improved Performance of Lithium Metal Batteries

Lithium metal batteries (LMB) have a higher specific energy density compared to lithium-ion batteries. However, they have the disadvantage that an inhomogeneous solid electrolyte interphase (SEI) forms on the lithium metal anode in contact with the electrolyte. As a result, the performance and cycle life of the battery are reduced. By applying a protective layer, this decomposition reaction can be prevented and a more uniform charge and discharge cycling of the cell can be achieved. A scientific team from MEET Battery Research Center at the University of Münster and from Helmholtz Institute Münster of Forschungszentrum Jülich has succeeded in optimizing such an intermetallic lithium-zinc protective layer by using a novel cryogenic analysis method and thus significantly improving the performance of the LMB cells. The publication “Tunable LiZn-intermetallic Coating Thickness on Lithium Metal and its Effect on Morphology and Performance in Lithium Metal Batteries” was published as Editor’s Choice in the specialist magazine Advanced Materials Interfaces.

Coating Thickness Determines Performance

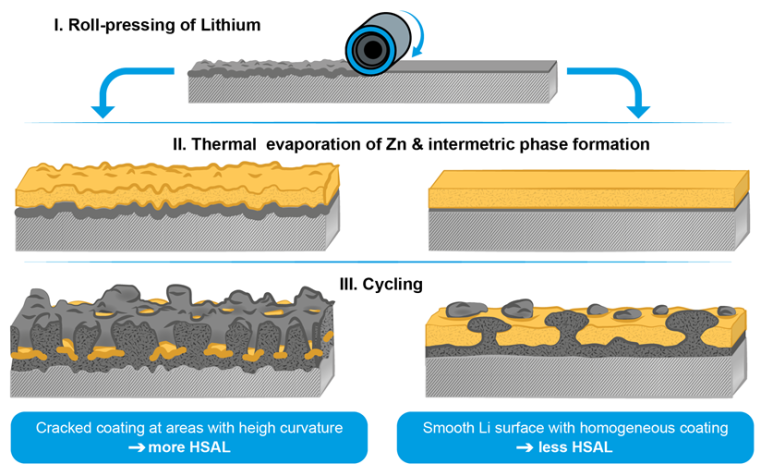

The researchers developed a new post-mortem analysis in which cross-sections of the lithium electrodes are exposed using cryogenic ion beam scanning electron microscopy at a temperature of -160 degrees Celsius. With this technique, the scientists were able to demonstrate that a thicker coating applied by thermal evaporation of zinc leads to longer protection of the lithium metal anode. “The high-resolution images show that the thickness of the layer not only determines the electrolyte decomposition, but also slows down the deposition of lithium during cycling, the formation of High Surface Area Lithium (HSAL),” MEET scientist Marlena Bela explains the results.

New Pre-treatment Method Further Improves Protective Layer

To further optimize the cells, the researchers employed roll-pressing of lithium metal foil as a pre-treatment before coating. During this treatment, the inhomogeneous passivation layer on the surface of the foil, which is formed by reactions of the lithium with the atmosphere, is removed using a roller that is guided over the metal under pressure. “If we detach this cracked layer and apply the coating to the smoothed surface, a more homogeneous intermetallic protective layer is created on which there is significantly less HSAL formation than when applied without roll-pressing,” explains Bela. The subsequent cross-sectional images showed that the cycle life of the cells improved significantly as a result of this procedure.

Entire Study Online Available

The detailed results of the study have been published by the authors Marlena M. Bela, Tobias Hering, Dr Markus Börner (MEET Battery Research Center) and Christina Schmidt, Dr Kerstin Neuhaus, Dr Marian Stan (Helmholtz Institute Münster of Forschungszentrum Jülich) and Prof. Dr Martin Winter (MEET Battery Research Center and Helmholtz Institute Münster) in the journal “Advanced Materials Interfaces”.