Precisely Tailored Water-based Binder Design for Sustainable and High-performance Cathodes

One strategy to achieve a more environmentally friendly, cost-effective, and energy-efficient battery production is to replace the environmentally harmful solvent N-methyl-2-pyrrolidone (NMP) with water. This is only possible in combination with a suitable, water-soluble binder. Carboxymethyl cellulose (CMC) is already widely used in graphite anodes of lithium ion batteries. However, its use in aqueously processed, nickel-rich high-energy cathodes still faces challenges. A team from MEET Battery Research Center at the University of Münster has therefore investigated how even small changes in the chemical structure of CMC influence the production and quality of the cathodes.

High Degree of Substitution Offers Advantages

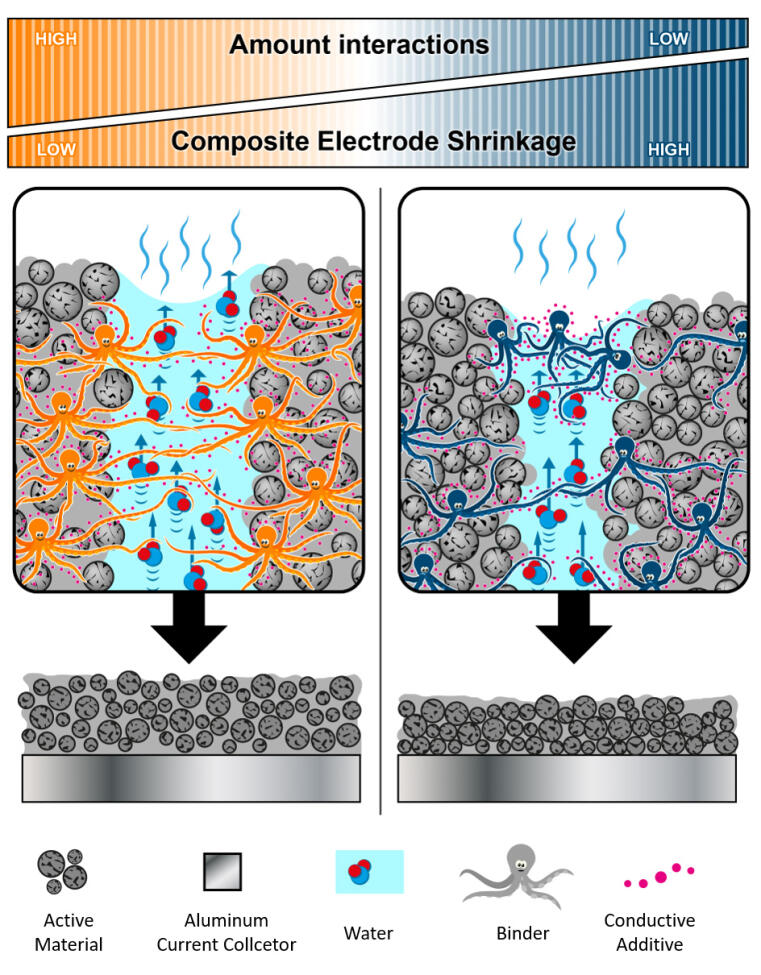

The researchers focused specifically on the degree of substitution (DC) of CMC, which indicates how many functional groups at the molecule are substituted. This has a substantial influence on the properties and performance of battery electrodes. “Previous studies have primarily focused on anodes. We now have conducted a comprehensive analysis of nickel-rich cathodes,” explains MEET scientist Johanna Kauling. The team demonstrated that a higher degree of substitution of 1.2 offers significant advantages over lower degrees of substitution such as 0.7 or 0.9. These improvements are a result of increased number of carboxy-groups, which ensure that the components of the electrode remain stably distributed in the aqueous paste and do not separate during the drying step. The outcome are electrodes with a homogeneous structure, increased electrical conductivity, and greater cohesion.

Another advantage is that the optimized binder leads to a considerably longer lifetime and improved fast-charging capability of the battery. Cells based on the high DS binder achieved 73 percent higher long-term stability performance than those based on the low DS binder. “Our results provide insights on how binders, water, conductive additive and active materials must interact at molecular level to produce ‘green’ and high-performance batteries,” Kauling summarizes.

Detailed Results Online Available

The entire study has been published by the authors Johanna Kauling, Chirag Vankani and Dr Markus Börner, MEET Battery Research Center, as well as Prof. Dr Martin Winter, MEET Battery Research Center and Helmholtz Institute Münster of Forschungszentrum Jülich, in the journal “Advanced Energy and Sustainability Research”.