Aluminum Fluoride Coating of Silicon Anodes Increases Battery Cell Performance

In order to exploit the promising potential of silicon (Si) as anode material in lithium-ion batteries (LIBs), it is necessary to overcome existing challenges such as capacity losses during battery operation. A team from MEET Battery Research Center, BACCARA International Graduate School at the University of Münster, and Helmholtz Institute Münster of Forschungszentrum Jülich demonstrated that coating silicon thin-film anodes with aluminum fluoride (AlF3) leads to an enhanced cycling stability. With their study, the researchers elucidated the mechanism and effects of AlF3 coatings on silicon thin-film anodes and provide important fundamentals on the further path to commercialization of the promising silicon-based lithium-ion batteries.

Aluminum Fluoride Coating Impacts Solid Electrolyte Interphase

During the initial charge cycles of LIB cells, the Solid Electrolyte Interphase (SEI) forms on the anode surface. However, Si anodes suffer from abrupt volume changes during lithiation/de-lithiation processes. Therefore, the unstable SEI cannot prevent parasitic reactions at the Si|electrolyte interface during operation, and thus does not prevent continuous electrolyte reduction and active lithium consumption. In their current study, the researchers therefore systematically investigated how AlF3 as a surface coating affects the composition of the SEI depending on the (de)lithiation state and protects the interface.

"The transformation of AlF3 to highly Li+ ion conductive Lithium-Aluminum-Fluoride phases (e.g., Li3AlF6) is responsible for the performance enhancement in cycling stability. The transformation of AlF3 will produce an abundant amount of LiF in the initial cycle which will inhibit the continuous SEI decomposition," explains Egy Adhitama, doctoral student at the International Graduate School of Battery Chemistry, Characterization, Analysis, Recycling and Application (BACCARA) and MEET Battery Research Center.

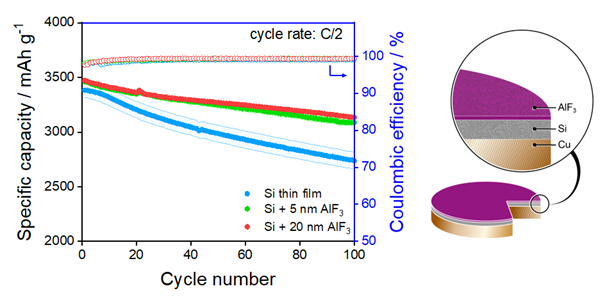

MEET scientist Dr. Aurora Gomez-Martin adds, "Once AlF3 is lithiated, it also possesses relatively high ionic conductivity. The coated Si thin films display a more stable and higher reversible capacity of ≈400 mAh g−1 after 100 cycles which is significantly better than the uncoated Si thin film cells."

Full Study Published in Advanced Energy Materials

Authors of the study are Egy Adhitama and Atif Javed, MEET Battery Research Center and International Graduate School BACCARA, Stefan van Wickeren, Lars Frankenstein, Feleke Demelash, Lukas Haneke, Dr Sascha Nowak, Dr Aurora Gomez-Martin and Dr Tobias Placke, MEET Battery Research Center, Dr Kerstin Neuhaus, Helmholtz Institute Münster, and Prof Martin Winter, MEET Battery Research Center and Helmholtz Institute Münster. The complete study has been published as an open access article in the journal "Advanced Energy Materials".