Innovative Material Concept for an Improved Silicon Anode

The lithium-ion battery is currently state of the art, but has not yet realised its full potential. New electrode materials such as silicon instead of pure graphite in the anode offer a significantly increased electrochemical performance. Until now, this has been at the expense of the battery's lifespan. Silicon expands enormously during charge and discharge operation, not only taking up more space, but also significantly reducing the number of possible charge and discharge cycles. In order to counteract the change in volume, a team of scientists with the participation of the MEET Battery Research Center has developed an innovative material concept for a composite based on silicon and graphite for the anode.

Strong cooperation for the sustainable battery of the future

"The battery of the future must combine all of these factors: higher energy density, a longer cycle life, maximum safety, improved sustainability and the lowest possible costs. That's what makes research challenging," explains Dr Tobias Placke, head of the Materials Division at the MEET Battery Research Center. Especially in electric mobility, higher energy densities are required to further increase the driving range of electric vehicles.

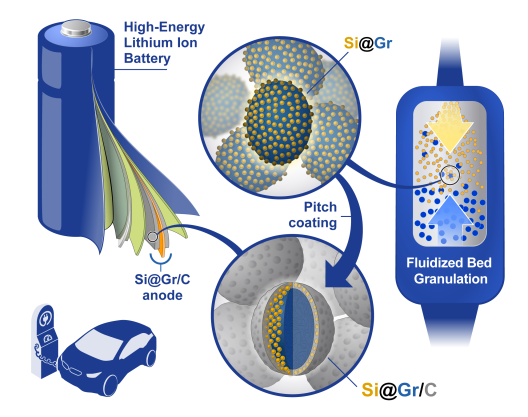

Since silicon as an anode material enables exactly this, the MEET Battery Research Center, TU Braunschweig and National Taiwan University have developed a novel silicon-on-graphite composites in a cooperative project. It consists of a graphitic core enclosed by two shells. The inner layer consists of silicon nanoparticles attached to the graphite particle surface („Si@Gr“), the outer layer is an amorphous carbon-coating („Si@Gr/C“). The research team used a fluidised bed granulation of the Technical University of Braunschweig for preparation of the Si@Gr structure. "When combined, the materials used now have properties that differ significantly from those of the individual components," says Placke. The fact that the silicon nanoparticles are now evenly distributed on the graphite surface of the core counteracts the volume changes of silicon on electrode level.

Results are part of a large-scale research project

The scientist Andrey Vinograd, Dr. Tobias Placke, Prof. Dr. Martin Winter of MEET Battery Research Center Jannes Müller, Markus Nöske, Christine Nowak, Dr. Wolfgang Haselrieder and Prof. Dr. Arno Kwade of the Technical University of Braunschweig as well as Shu-Jui Chang, Dr. Mozaffar Abdollahifar and Prof. Nae-Lih Wu of National Taiwan University have published the detailed results in the "Chemical Engineering Journal". The study is embedded in the project "LiBEST - Lithium-ion battery with high electrochemical performance and safety", which is funded by the Federal Ministry of Education and Research.