ERC Grant SUPERFOAM

Foams are ubiquitous in our daily lives be it as milk foam on our cappuccino or as heat insulation of the building we live in.

The various important technological applications range from lightweight materials, waste water treatment to recycling of rare earth metals via ion flotation just to mention a few.

The vast number of possibilities to use foam in industrial processes and products originate from a unique tunability of optical, mechanical as well as chemical properties. This makes foams to an exciting object of current interdisciplinary research.

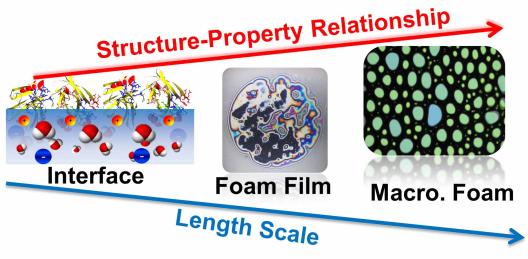

Although making aqueous foam is surprisingly easy as one “simply” has to lower the water’s surface tension by additions of surface active molecules, the foam is in most cases inherently unstable. Furthermore, foam formulation is usually performed purely empirically because the actual driving forces must be controlled on several length scales that reach down to the molecular level. For that reason understanding and controlling foam properties with a bottom-up approach is a major challenge in current research.