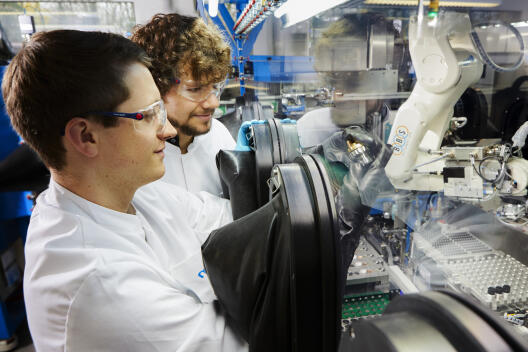

Material Design, Characterization and Synthesis at the Highest Level

A key role in developing existing and new sustainable batteries of the future is played by the materials used. These materials determine important features of batteries such as energy density, performance, lifetime, safety, costs and sustainability. Our researchers working in this field develop new battery materials and optimize existing ones. The aim is to improve energy storage systems, adapting them precisely for the use to which they will be put, or to open up new areas of use. Also, the team decodes complex mechanisms in the materials in the battery cells – which is the precondition for developing a better understanding of the processes and reactions taking place. In its work, the team can draw on wide-ranging experience, especially in the development and synthesis of electrochemical energy storage materials. It has already been granted numerous patents, relating for example to electrolyt additives.

Innovative Materials for Inexpensive and Sustainable Batteries of the Future

It is lithium-ion batteries which dominate the market nowadays. Light, compact and with an unprecedented energy and power density, this is currently a successful technology – and one which will also play a decisive part in energy storage in the future. A battery system which could soon provide a widespread substitute for lithium-ion batteries is not yet in sight. This makes it all the more important – and more challenging – to continue developing, and to optimize, existing technology and the materials it uses. After all, the expectations that people will have in the future are high, especially as regards electromobility and stationary storage solutions. Lithium-ion batteries need to become ever more efficient, cost-effective, and sustainable.

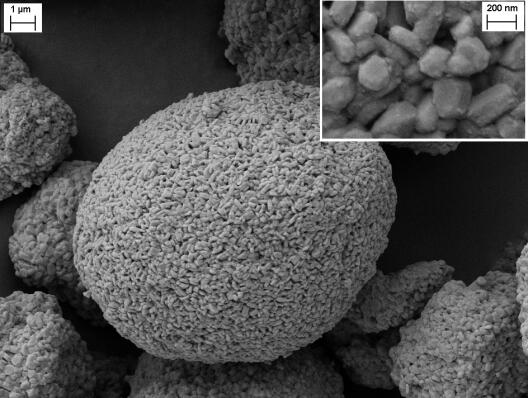

For this to succeed, our team in the materials department concentrates its research work on active storage materials for the positive and negative electrodes in lithium-ion batteries. These active materials have the greatest influence on the characteristics of the battery cell and so they provide researchers with a crucial starting point for their work. An important role is also played by the work carried out on inactive materials in battery electrodes such as binders, electrical conductors or electrically conductive carbon black. A further component is research on materials for alternative energy storage systems apart from lithium-ion technology. Here, with its work on dual-ion batteries (where our researchers hold two basic patents), the MEET team is among the leading groups worldwide working in this field.

The expectations that people will have in the future are high, especially as regards electromobility and stationary storage solutions. Lithium-ion batteries need to become ever more efficient, cost-effective, and sustainable.