Our Research

We are working in research and teaching of Materials Physics with a strong focus on:

© IMP

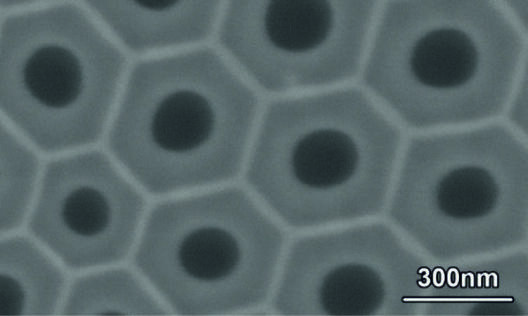

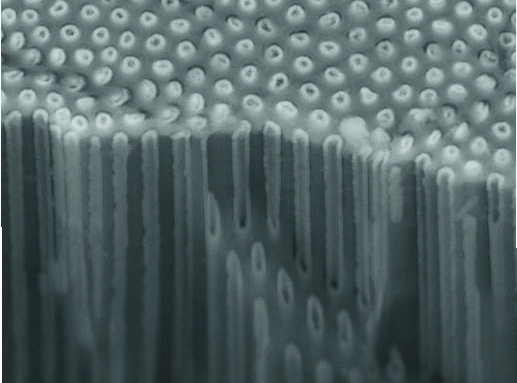

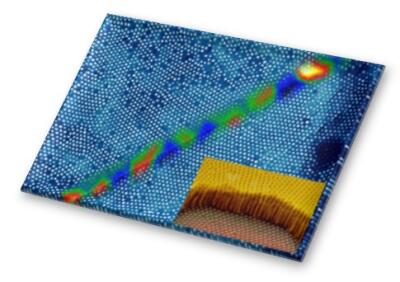

© IMP Surface Nano-Structuring

UTAM (ultra-thin alumina mask) surface nano-patterning is an emerging technique in synthesizing ordered arrays of surface nanostructures (nano-dots, nanoholes, nanowires and nanotubes). It provides an efficient and well-controlled alternative in fabricating ordered arrays of surface nanostructures. Compared to other surface nanopatterning processes, the UTAM technique has advantageous features such as tuneable structural parameters and controllable properties, large pattern area and high throughput, low equipment costs, and general applicability in fabricating surface structures. The large-scale and well-defined surface nanostructures that are prepared using the UTAM technique are good candidate structures for the next generation of nano-devices.

Contact: Prof. G. Wilde

Atomic Transport in Nano-Scaled and Low-Dimensional Structures

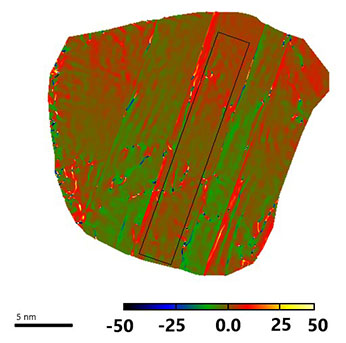

Kinetic properties of interfaces are crucial for many advanced technological applications and determine the long-time stability of modern constructions. In addition, diffusion analyses provide a structure-sensitive probe for bulk quantities that is particularly sensitive for atomic-scale defects. We are interested in detailed studies of atomic transport in submicron- and nano-scaled materials produced by a variety of modern methods. Especially the diffusion properties of low dimensional structures (grain and interphase boundaries, dislocations, pores) are in the focus of our current research. A special attention is paid into the interrelation of diffusion kinetics and plastic deformation properties of nanocrystalline metallic materials. The radiotracer measurements in our well-equipped and world-leading laboratory are combined with thorough structure characterisation using TEM, high-resolution TEM, SEM, FIB, X-ray and optical microscopy techniques.

Contact: PD Dr. S. Divinsyi, Prof. G. Wilde

© IMP Plasticity in Fine Grained Materials

Plasticity in a metal usually proceeds through the formation of dislocations. Dislocations are line defects in crystalline structures which can travel through the crystal lattice in a similar manner to a fold moving through a carpet. In order to generate dislocations one requires a source known as a Frank-Read source. Metals are usually polycrystalline i.e., they are composed of many individual crystallites or grains. The size of the individual grains can range from several centimeters to nanometers. However, a certain minimum grain size is required to allow production of dislocations from a Frank-Read source. Thus as the grain size in a metal is reduced, somewhere in the nanoscale regime (<100nm), a change from dislocation-mediated deformation to grain boundary-mediated deformation occurs. Our current research investigates both of these deformation mechanisms in detail and also examines at which grain size the change in mechanism takes place in a material. This is achieved through carefully chosen experiments and computer simulations.

Contact: Dr. H. Rösner, Prof. G. Wilde

Phase Transformations in Nanoscale Systems

Stability and functionality of any given material crucially depend on the occurrence of phase transformations. However, little is known about the underlying physics that determines if, how and why both thermodynamics and kinetics of phase transformations become size dependent when the size of the system is reduced to nanometer dimensions. We analyze experimentally as well as by analytical modelling how the basic interrelations between system size, defect structure, interface topology and modifications of the thermodynamics and kinetics of reversible phase transformations can be described on the basis of constitutive equations. To reach this goal, different synthesis methods and calorimetry techniques available in our fully-equipped thermal analyses laboratory are combined with state-of-the-art structure characterisation methods including TEM, high-resolution TEM, SEM, AFM, FIB, X-ray and optical microscopy techniques.

Contact: Dr. H. Rösner, Prof. G. Wilde

© IMP Metallic Glasses

Metallic glasses possess unique properties such as a high elastic limit, large resistance against corrosion, superplastic formability or metallic conductivity. In addition, metallic glasses are model materials that allow experimenttally analyzing the early stages of crystalline order formation as well as experimentally assessing dynamic properties and localized deformation behaviour that are characteristic for structurally disordered states. We synthesize metallic glasses via several different quenching or deposition routes and perform calorimetry and dilatometry for analyzing the kinetics and dynamics of relaxation. Additionally, plastic deformation processing with subsequent structural characterization by TEM, high-resolution TEM, AFM, FIB, X-ray and optical microscopy techniques is performed in order to analyze the basic physical mechanisms that accommodate external stresses in disordered solids.

Contact: Prof. G. Wilde